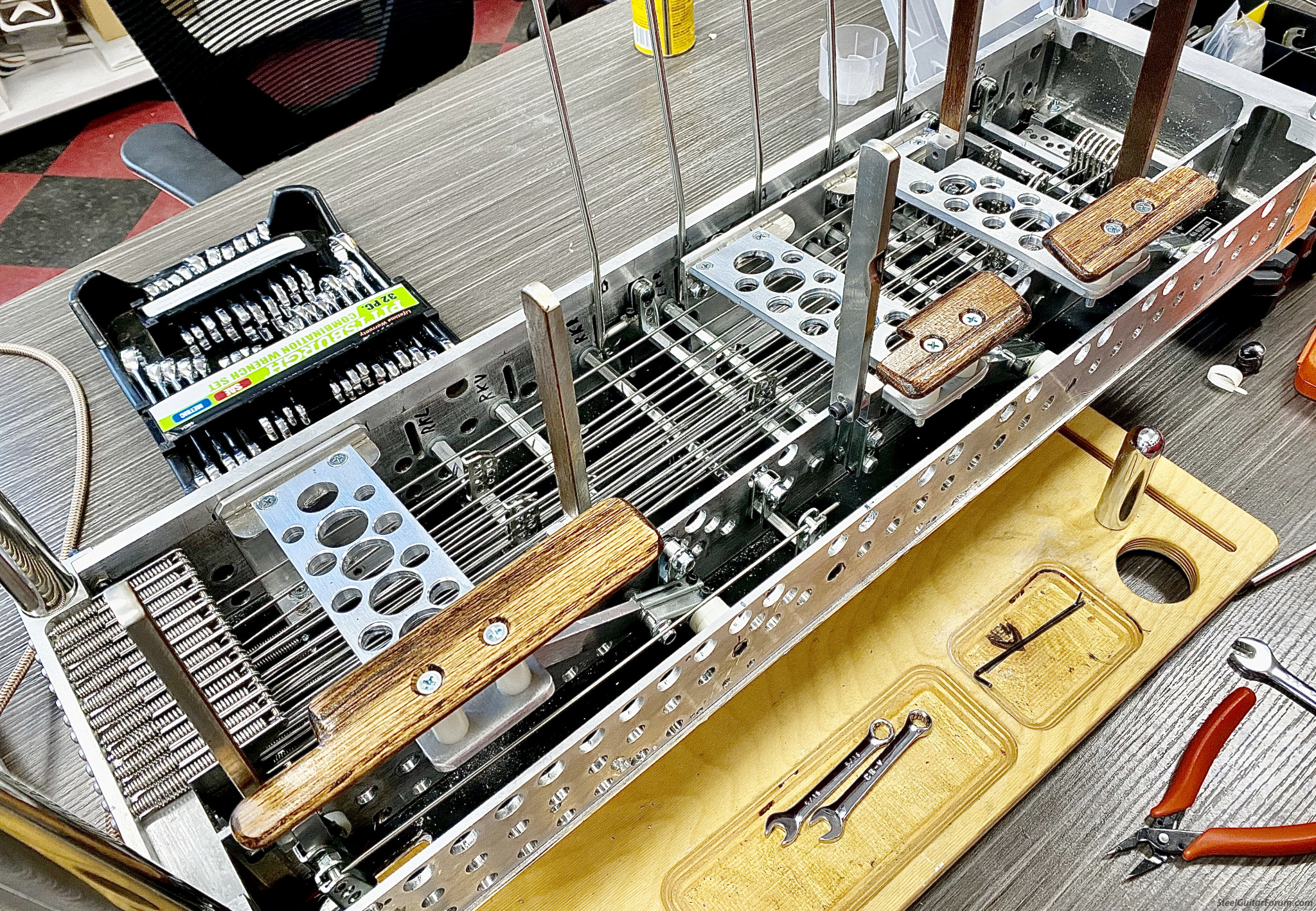

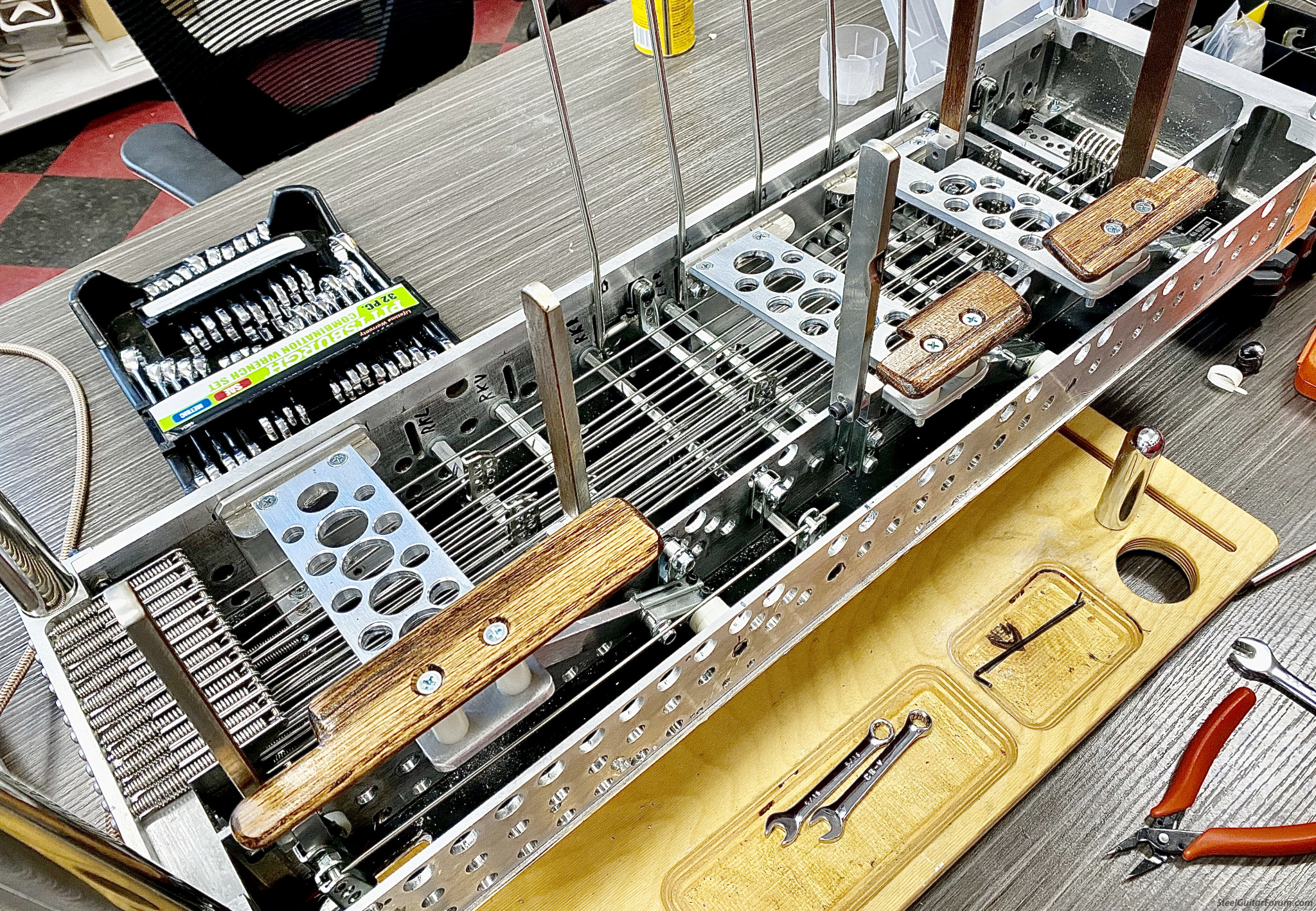

Just finished that little Excel Superb with 2 front-hinged V-levers and am very pleased with the result:

Here are some pictures:

Both the RKV and both LKV required a front-hinge bracket as this guitar has NO wood in the front to drill into. I could therefore NOT drill the hinges into the front apron.

Anyways, LKV's had to be cleared off the pedal hookup-cranks no matter what. So, I made "L"-brackets for both.

LKV's "L"-brackets had to be drilled to let the cross-shafts pass. They are screwed into the top of the guitar (screw holes thru into the wood neck above).

Here are two function videos:

Basic functioning:

https://www.dropbox.com/s/wz8y6io3h673b ... .MOV?raw=1

As you will see, besides the front-hinge levers and their hinge-bracket and the "reader-finger" which is lodged in a pair of closed OEM-Excel bell-cranks, pretty much all is OEM-Excel parts: the stops, cross shaft and bell cranks.

Leg-Room and cross-function achieved (being able to play a V-lever and add a regular lever too it with the same leg):

https://www.dropbox.com/s/u6ugsp9yilnc1 ... .MOV?raw=1

Since the "reader"/"actuator" which is born at the cross-shaft, reads the front-hinged actuator-paddle pretty much in the middle of the V-lever, TORSION is an issue.

I started with two-legged 1/16" shape-reinforced paddle which would give on both sides. The paddles need to be very rigid to torsion. I should that 1/4" material seemed to be the solution. I needed to be wide at both end.

Evidently, mass becomes an issue not just for transportation but for acceleration (inertia). I tested drilling them (as seen above) reducing mass by 50% without loosing resistance to torsion noticeably. I think they could also have been "bone" shaped and even the center of the "bone" still drilled, as long one maintains wide "feet" at both ends and material thickness.

I played the guitar only briefly, because I was to take an Int'l trip, but carry that "li'l" guitar with me.

... J-D.